Lead-Free PCB Assembly at PCBasic Building Reliable and Sustainable Electronics

As environmental regulations tighten and global markets demand higher compliance standards, lead-free PCB assembly has become the default choice for modern electronics manufacturing. From consumer devices to industrial control systems, PCBA manufacturers are shifting away from traditional leaded solder in favor of safer, eco-friendly alternatives.

At PCBasic, lead-free PCB assembly is not an optional service—it is a fully integrated manufacturing standard designed to deliver reliability, regulatory compliance, and long-term product performance.

What Is Lead-Free PCB Assembly?

Lead-free PCB assembly refers to the process of assembling printed circuit boards using solder alloys and materials that contain no restricted levels of lead, in accordance with RoHS and related environmental directives.

Instead of traditional tin-lead solder, lead-free assembly typically uses alloys such as tin-silver-copper (SAC). These materials eliminate hazardous lead content while maintaining strong mechanical and electrical performance, making them suitable for a wide range of applications.

Today, lead-free assembly is a baseline requirement for products entering markets such as Europe, the UK, North America, and many parts of Asia.

Why Lead-Free PCB Assembly Is Essential

Environmental Responsibility

Lead is a toxic substance that poses risks during manufacturing, product use, and disposal. Eliminating lead from soldering processes significantly reduces environmental pollution and improves workplace safety, aligning electronics production with modern sustainability goals.

Regulatory Compliance

Many international regulations restrict or prohibit the use of lead in electronic products. Lead-free PCB assembly ensures compliance with these regulations, preventing customs issues, recalls, or market access limitations.

Long-Term Market Competitiveness

Beyond compliance, lead-free manufacturing enhances brand credibility. Customers increasingly favor suppliers that demonstrate environmental responsibility and forward-looking manufacturing practices.

Lead-Free vs. Leaded PCB Assembly: Key Differences

While lead-free assembly offers clear advantages, it also introduces technical challenges that require advanced process control.

| Aspect | Leaded Assembly | Lead-Free Assembly |

| Solder Alloy | Tin-lead (SnPb) | Tin-silver-copper (SAC) |

| Melting Temperature | Lower | Higher |

| Environmental Impact | Hazardous | Eco-friendly |

| Regulatory Acceptance | Limited | Widely accepted |

| Process Control | More forgiving | Requires precision |

The higher reflow temperatures used in lead-free soldering demand careful thermal profile design, material selection, and equipment stability—areas where manufacturing expertise is critical.

Lead-Free PCB Assembly Process Overview

A high-quality lead-free PCB assembly process typically includes the following steps:

- Material and BOM Verification

All PCBs, components, solder pastes, and surface finishes must be verified as lead-free and compliant with applicable regulations.

- Solder Paste Printing

Lead-free solder paste is applied using precision stencils to ensure consistent solder volume and alignment.

- Component Placement

High-accuracy pick-and-place machines position components to meet fine-pitch and high-density design requirements.

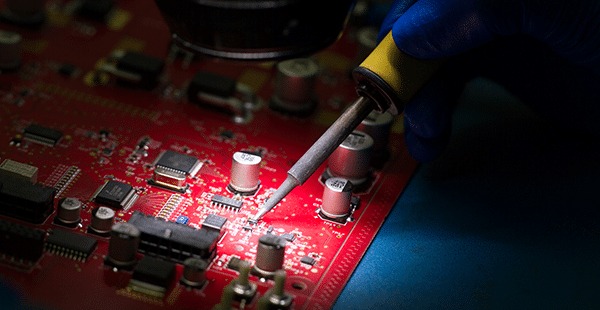

- Reflow Soldering

Controlled lead-free reflow profiles are used to form reliable solder joints without damaging sensitive components.

- Inspection and Testing

AOI, X-ray inspection, and electrical testing verify solder joint quality, component placement, and functional performance.

- Final Assembly and Packaging

Boards that pass inspection proceed to final assembly, optional coating, and secure packaging for delivery.

PCBasic’s Lead-Free PCB Assembly Capabilities

PCBasic has established a mature lead-free manufacturing system designed for both prototype and mass production.

Fully Lead-Free Production Environment

All SMT and through-hole assembly lines operate under lead-free standards. Materials are strictly controlled to prevent cross-contamination and ensure consistent compliance across every order.

Advanced Process Engineering

PCBasic engineers optimize reflow profiles, stencil design, and assembly parameters specifically for lead-free solder alloys, ensuring strong solder joints and stable long-term reliability.

Comprehensive Quality Control

Multiple inspection stages—including SPI, AOI, X-ray, and functional testing—are integrated into the production workflow to detect defects early and maintain high yield rates.

Certified Manufacturing Standards

PCBasic follows internationally recognized quality and environmental management systems and builds to IPC workmanship standards, supporting applications that demand high reliability.

One-Stop PCB and PCBA Services

From PCB fabrication and component sourcing to lead-free assembly, testing, and final delivery, PCBasic provides an end-to-end manufacturing solution that simplifies supply chains and shortens project timelines.

Applications of Lead-Free PCB Assembly

PCBasic’s lead-free PCB assembly services are widely used in:

- Consumer electronics

- Industrial automation and control systems

- Automotive electronics

- Medical devices

- IoT and communication equipment

Each application benefits from improved compliance, reduced environmental impact, and consistent manufacturing quality.

Conclusion

Lead-free PCB assembly is no longer just a regulatory requirement—it is a key indicator of modern, responsible electronics manufacturing. Achieving reliable lead-free assembly requires not only compliant materials, but also precise process control and experienced engineering support.

With its fully integrated lead-free production lines, rigorous quality systems, and one-stop PCBA services, PCBasic helps customers deliver compliant, reliable, and future-ready electronic products to global markets.

Whether you are developing a prototype or scaling to mass production, choosing PCBasic as your lead-free PCB assembly partner ensures quality, consistency, and sustainability at every stage.