Industrial Safety Barrier and Polymer Barrier Solutions for Modern Facilities

In industrial environments, safety is not a preference — it is a core operational requirement. Continuous machine movement, heavy equipment traffic, and shared areas between personnel and vehicles create conditions where even small incidents can escalate into major disruptions.

As facilities grow in scale and workflow intensity, the demand for durable, adaptable, and long-lasting protection systems becomes essential. For this purpose, safety barrier and polymer barrier systems provide engineered protection designed to safeguard infrastructure, equipment, and workers with high efficiency.

Safety Barrier — A Strategic Defense for Industrial Workplaces

A safety barrier is one of the most critical elements of a secure industrial layout. It forms a controlled separation line that prevents machinery from entering pedestrian routes or restricted sections. In warehouses, logistics halls, and production centers, safety barriers are key to reducing collision probability and ensuring an organized flow of operations.

Raysan safety barrier solutions are built for visibility, durability, and functional workplace control. Instead of simply blocking movement, these systems actively guide traffic flow and prevent collisions before they occur.

Whether installed around sensitive machinery, production corridors, or loading zones, safety barrier systems reinforce workplace safety and operational discipline.

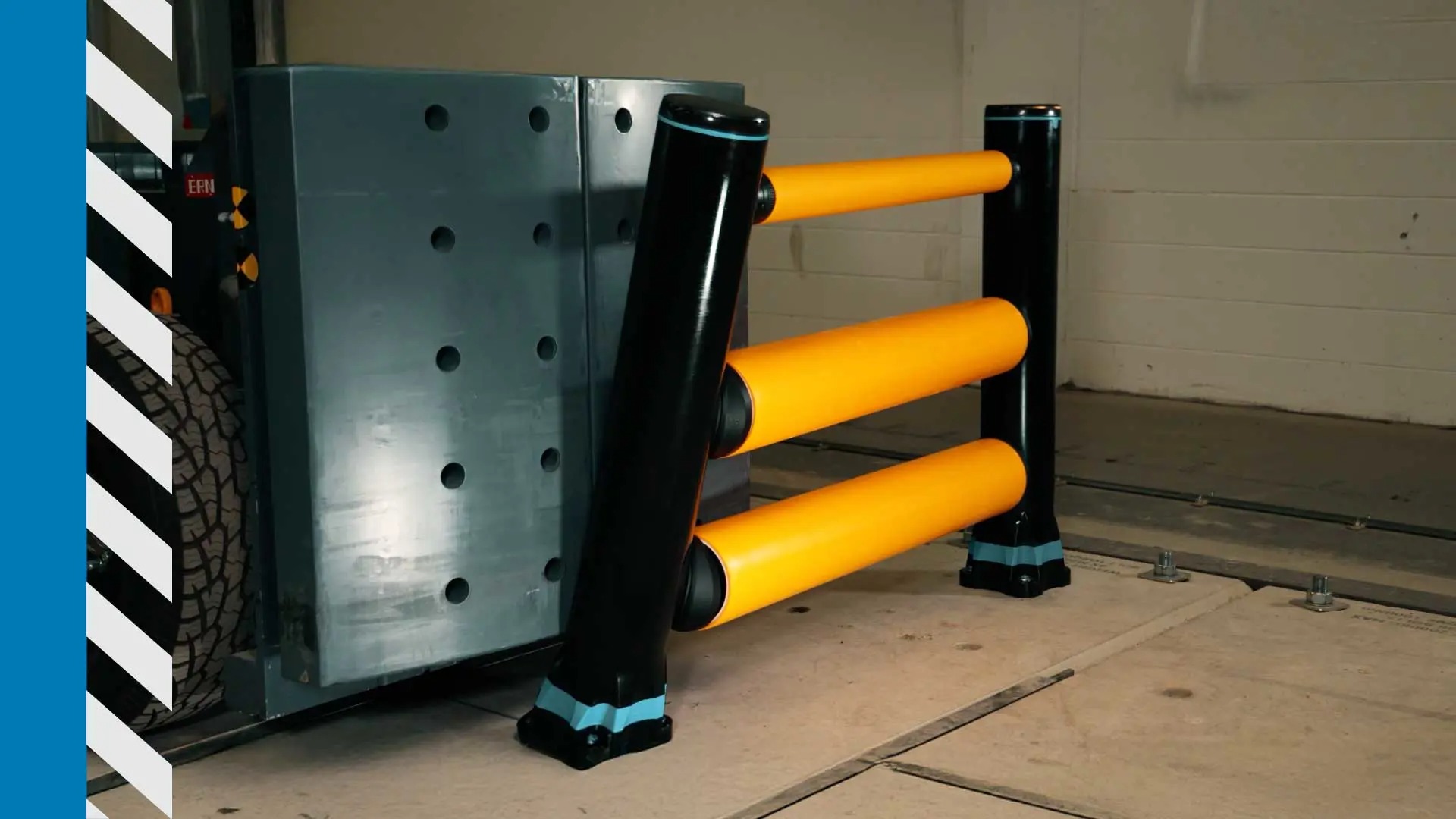

Polymer Barrier — Flexible Shock Absorption and Impact Recovery

Conventional metal barriers remain rigid under impact and transmit collision force directly into the floor, rack, or structure they protect. In contrast, polymer barrier systems are engineered to absorb and distribute kinetic energy instead of transferring it.

Made from high-performance, recyclable polymer materials, these barriers bend and flex under pressure, then return to their original form — preventing structural damage and eliminating costly repair cycles.

Key advantages of polymer barrier technology include:

- High shock-absorption and impact flexibility

- No cracking, rusting, corrosion or repainting

- Significantly extended lifetime with minimal maintenance

- Ideal for high-traffic industrial environments

In applications where forklifts and heavy vehicles move continuously, polymer barrier provides a sustainable, long-term protective alternative to rigid steel solutions.

Sustainability & Operational Efficiency

Both safety barrier and polymer barrier systems offer long-term durability with environmental responsibility. Their recyclable composition and maintenance-free design reduce operational cost while minimizing material waste throughout product lifespan.

Less downtime, fewer replacements, and uninterrupted workflow result in stronger financial efficiency for industrial facilities.

Why This Matters for Modern Industry

Industrial plants need more than simple physical protection — they need systems that support continuous movement, prevent impact-related downtime, and protect personnel with measurable reliability. Safety barrier and polymer barrier technology provides exactly that.

Advantages at a glance:

Impact-absorbing performance

Long lifecycle & near-zero maintenance

Modular and scalable installation

Fully recyclable structure

Increased workplace awareness & safety discipline

These solutions do not merely reinforce workplace safety — they shape the next generation of high-performance, low-maintenance, sustainable industrial protection.

Disclaimer:

This article is provided for general informational and educational purposes only. It does not constitute engineering, safety, legal, or regulatory advice. Any references to safety barrier or polymer barrier systems, including brand or product mentions, are illustrative and do not imply endorsement, affiliation, or a guarantee of performance. Actual safety requirements, system suitability, installation methods, and compliance obligations vary by facility, industry, and jurisdiction. Readers should consult qualified safety professionals, engineers, and relevant regulatory authorities before selecting or installing any industrial safety solutions.